The Metal Bipolar Plate Molding output Line is in the forefront of technological improvements in gasoline mobile production. Designed with precision and effectiveness, it makes certain the large-high quality manufacture of metal bipolar plates, which can be essential components in gasoline cells. the procedure requires a number of crucial methods, Each and every optimized for max productiveness and accuracy, to satisfy the rising calls for with the renewable Power sector.

Table of contents:

Overview on the Stamping course of action

Cleaning, Welding, and Coating treatments

Sealing and tests Protocols

Integration of MES and Intelligent Logistics units

Overview in the Stamping Process

The stamping course of action would be the very important Preliminary phase in the creation of metal bipolar plates, laying the muse for their operation in different apps, specially gas cells. this method requires the usage of Highly developed molding techniques to create intricate and really detailed models with specific requirements that make sure optimum overall performance. The molds play an important job in protecting uniformity and precision, as even the slightest deviation could affect the effectiveness of the bipolar plates. to obtain this, higher-powered hydraulic presses, able to producing nominal forces of up to twenty,000 kN, are employed. These presses not simply present the necessary drive to condition the metallic but also boost generation effectiveness by way of speedy stamping cycles. This minimizes creation time, lessens costs, and maximizes throughput, enabling producers to satisfy the increasing demand for top-efficiency gasoline mobile components. Each individual move is meticulously controlled to ensure good quality and reliability, producing the stamping system an indispensable Element of the manufacturing chain.

Cleaning, Welding, and Coating Procedures

following stamping, the plates endure a radical cleansing course of action to eliminate any contaminants, for example oils, particles, or residues, ensuring a easy, pristine floor for the following generation techniques. Highly developed cleansing units are utilized, which can be customized to fulfill particular generation requirements regarding size and throughput, optimizing effectiveness for giant-scale producing. the moment cleaned, precision laser welding is accustomed to be part of the stamped plates, making entire bipolar plates. this method makes sure a high volume of precision, with laser welding giving Extraordinary regularity, energy, and durability within the welds. using substantial-high quality products, coupled with rigid good quality Management requirements, guarantees the trustworthiness and longevity of the ultimate merchandise. immediately after welding, the plates are subjected to the specialised floor cure that improves their resistance to corrosion, improves Total durability, and boosts general performance in demanding environments, building them well suited for cutting-edge purposes for instance gasoline cells and Sophisticated Electricity systems.

Sealing and screening Protocols

Sealing and testing are crucial to guaranteeing the dependability and efficiency of steel bipolar plates Employed in gasoline cells. higher-high quality sealing actions are meticulously carried out to make certain airtight disorders, that are important for the efficient Procedure of gasoline cells by protecting against any fuel leakage that could compromise overall performance. These sealing methods frequently entail State-of-the-art components and precision application approaches to withstand various operational circumstances. Together with sealing, arduous testing protocols are conducted to evaluate strength, durability, and Over-all general performance. These checks simulate real-earth circumstances, such as publicity to Serious temperatures, pressure adjustments, and very long-time period use, making sure that Just about every plate meets or exceeds business criteria. The tests approach may include things like chemical resistance assessments to verify the plates' potential to function effectively in remarkably reactive environments. these types of meticulous sealing and tests procedures safeguard the plates' features and make sure their extensive-time period reliability throughout A selection of gasoline mobile applications, from portable units to big-scale energy systems. This thorough method delivers people with confidence in the performance and toughness in their gasoline mobile devices.

Integration of MES and Intelligent Logistics techniques

The steel Bipolar Plate Molding output Line incorporates Superior production Execution units (MES) and smart logistics systems for best workflow administration. MES systems provide serious-time monitoring and Charge of the creation approach, making sure that each phase runs easily. clever logistics further more streamline content dealing with, feeding operations, and discharge processes. With precision feeding methods allowing accuracies of ±0.2 mm/m and discharge line speeds of nearly 16 m/min, efficiency is enhanced, lessening delays and making certain seamless operation.

The steel Bipolar Plate Molding creation Line embodies point out-of-the-art know-how and innovation. Its Innovative processes, from stamping to tests, coupled with automation through MES and clever logistics, enable it to be a essential Device for brands in the gas mobile marketplace. It don't just supports large-quantity, excellent manufacturing but will here also accelerates the adoption of sustainable Power solutions. should you’re seeking to boost your gas cell production capabilities, the metallic Bipolar Plate Molding output Line delivers the precision, performance, and reliability you'll need.

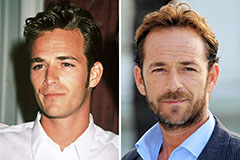

Luke Perry Then & Now!

Luke Perry Then & Now! Richard "Little Hercules" Sandrak Then & Now!

Richard "Little Hercules" Sandrak Then & Now! Robert Downey Jr. Then & Now!

Robert Downey Jr. Then & Now! Macaulay Culkin Then & Now!

Macaulay Culkin Then & Now! Andrew McCarthy Then & Now!

Andrew McCarthy Then & Now!